If you search “what is wire mesh” on Google, you’ll find hundreds of pages defining it as a material made from interwoven, welded, or connected metal wires arranged in a regular pattern. On the surface, the concept sounds simple — and that’s exactly where many buyers are misled.

Most buyers don’t fail because they don’t know what wire mesh is — they fail because they assume all wire mesh works the same way.

In reality, wire mesh is not a single product but a broad category of engineered materials. Different wire diameters, opening sizes, production methods, and surface treatments can lead to completely different performance outcomes, costs, and service life.

This guide doesn’t just explain what wire mesh is in theory. It helps you understand how to think about wire mesh in real-world use, so you can avoid costly mistakes and confidently choose the right solution for your specific application.

Table of Contents

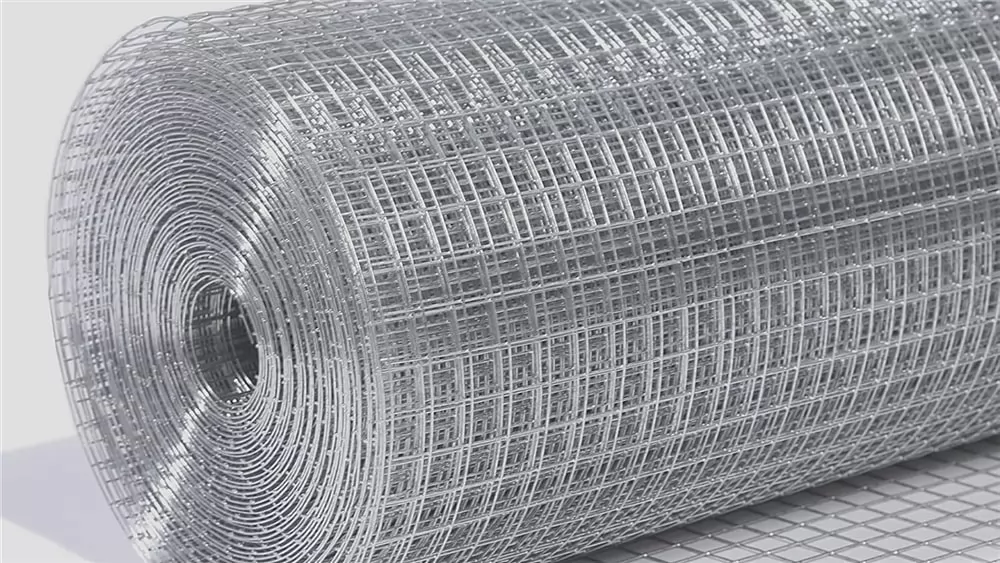

Wire mesh, also known as wire cloth or wire fabric, is a grid-like material made by weaving or welding metal wires together into a sheet with evenly spaced openings. Depending on its construction, wire mesh can feature square, rectangular, or even decorative patterns, making it an extremely versatile material used across industries worldwide.

The versatility of wire mesh comes from the endless combinations of wire diameters, opening sizes, and materials such as stainless steel, galvanized steel, aluminum, brass, and copper. This flexibility allows it to serve thousands of functions, from industrial filtration, sieving, and mining to architectural design, safety barriers, insect screening, and even artistic installations.

In industrial settings, wire mesh is critical for separation, filtration, and reinforcement applications, while in commercial and residential use, it is widely seen in fencing, railing infill panels, window guards, and ventilation covers. Its durability, adaptability, and cost-effectiveness make it a go-to material in sectors like construction, automotive, agriculture, food processing, oil refining, and electronics.

At first glance, wire mesh appears to be one of the simplest metal products on the market. It consists of straight metal wires, evenly spaced openings, and is usually sold in rolls or rigid panels. Because it looks straightforward, many people assume that choosing wire mesh is a low-risk decision.

In practice, wire mesh selection is rarely about appearance or basic dimensions. It is a technical decision that directly affects strength, corrosion resistance, lifespan, safety, and long-term cost. Two wire meshes that look almost identical can perform very differently once installed.

The most common mistake is focusing on a single factor — usually price, opening size, or availability — while ignoring how other variables interact with each other. When this happens, the mesh may still “fit,” but it fails to perform as expected over time.

This is why many wire mesh issues are discovered months after installation, not immediately. By the time rust appears, welds fail, or panels begin to deform, the real problem is no longer the product itself — it is the original selection decision.

Many people assume that wire mesh is a standard product. As long as the opening size looks right and the price is acceptable, they believe it will work.

In reality, wire mesh does not work this way. Different wire meshes are designed to solve different problems, and choosing the wrong one often leads to poor performance or early failure.

Wire mesh selection is not about finding the “best” option. It is about understanding what matters most for your specific application and what you can compromise on.

Every wire mesh design is a balance between several key factors. Changing one factor almost always affects the others.

Thicker wires make the mesh stronger and more rigid. This is important for load-bearing, security, and protective applications.

Larger openings allow better airflow, drainage, visibility, or material flow. These features are critical for fencing, screening, and ventilation.

Because space is limited, wire mesh cannot maximize strength and open space at the same time. Choosing the wrong balance often results in sagging, bending, or reduced functionality.

Lower-cost wire mesh may seem attractive at first, especially for large projects. For indoor or short-term use, this choice may be acceptable.

However, in outdoor or corrosive environments, insufficient coating or improper material selection can lead to rust and failure much sooner than expected.

In many cases, spending slightly more upfront results in fewer replacements, lower maintenance costs, and better long-term value.

Welded wire mesh is rigid and holds its shape well. It is commonly used for panels, fencing, cages, and reinforcement where stability is required.

Woven wire mesh is more flexible and better suited for filtration, screening, and applications involving vibration or movement.

Using the wrong construction type may not cause immediate problems, but it often limits performance and shortens the service life of the mesh.

Choosing wire mesh becomes much easier when you stop comparing product names and start answering a few practical questions. You do not need engineering experience to make a good decision. You only need to understand how the mesh will be used.

Before selecting any wire mesh, ask yourself the following four questions.

Start with the primary function. Is the mesh meant to support weight, provide security, allow airflow, filter materials, or simply create a visual barrier?

Load-bearing and security applications require thicker wires and stronger construction. Filtering, ventilation, or screening applications usually prioritize open area and precision over strength.

The environment plays a major role in material and coating selection. Indoor applications face far fewer challenges than outdoor ones.

For outdoor, coastal, or industrial environments, corrosion resistance becomes critical. In these cases, hot-dip galvanized or stainless steel wire mesh is often a better long-term choice than lightly coated alternatives.

If the mesh must hold its shape, remain flat, or be installed as panels, welded wire mesh is usually the better option.

If the mesh needs to flex, vibrate, or be rolled frequently, woven wire mesh typically performs better and lasts longer.

For temporary use, such as construction barriers or short-term enclosures, lower-cost options may be sufficient.

For permanent installations, choosing a more durable mesh often reduces maintenance, replacement costs, and downtime over the life of the project.

By answering these questions first, you can narrow down suitable wire mesh options quickly and avoid costly mistakes later.

Choosing the right material for wire mesh is crucial. The wrong choice can lead to rust, breakage, or higher costs. Here’s a simple breakdown of the most common options:

Galvanized wire mesh is coated with zinc to prevent rust and corrosion. It is widely used in fencing, garden projects, and temporary barriers.

Pros: Affordable, rust-resistant, widely available, easy to cut and install.

Cons: Coating can wear over time outdoors; not ideal for heavy industrial use.

PVC-coated mesh has a plastic layer over galvanized steel, offering extra protection and color options.

Pros: Extra corrosion resistance, safer to handle, longer-lasting outdoors, available in green, black, and white.

Cons: Slightly higher cost; coating may scratch if handled roughly.

Made entirely from stainless steel, this mesh is highly durable and corrosion-resistant, suitable for industrial, architectural, and marine applications.

Pros: Long-lasting, high strength, corrosion-proof, ideal for critical applications.

Cons: More expensive; harder to cut without proper tools.

Lightweight and rust-resistant, aluminum mesh is used in decorative projects, screens, and some industrial applications.

Pros: Lightweight, easy to handle, corrosion-resistant.

Cons: Lower strength, not suitable for heavy-duty fencing or concrete reinforcement.

Understanding the pros and cons of each material ensures you choose the right wire mesh for your specific project, reducing risk and unnecessary costs.

Choosing the right size, opening, and gauge of wire mesh is as important as selecting the material. These specifications determine the mesh’s strength, flexibility, and suitability for your project.

The mesh size refers to the distance between wires, usually measured in inches or millimeters. Smaller openings are stronger and can keep out small animals, while larger openings are lighter and allow more airflow.

Example: 1/2 inch openings are common for poultry fencing, while 2 inch openings may be enough for garden trellises.

Wire gauge indicates the thickness of the wire. Thicker wire is stronger and more durable, but less flexible. Thinner wire is easier to cut and bend but may not hold up under heavy stress.

Tip: Use 14-16 gauge for general fencing and 10-12 gauge for heavy-duty security or concrete reinforcement.

Wire mesh is sold in rolls or pre-cut panels. Rolls are flexible and great for fencing long stretches, while panels are easier to install for smaller projects or precise layouts.

Tip: Choose panels if you want uniform size and a neat appearance; choose rolls for longer, continuous applications.

Understanding these specifications will save you time, prevent mistakes, and ensure that your wire mesh performs exactly as you need.

Once you know the type, size, and gauge of wire mesh you need, the next step is finding a reliable supplier. Different buyers have different needs—DIYers, contractors, and industrial purchasers all require different sources.

For small DIY projects, garden fencing, or pet enclosures, local home improvement stores are convenient. They usually carry galvanized, PVC-coated, and stainless steel wire mesh in rolls or panels.

Popular Options: Home Depot, Lowe’s, B&Q (UK)

Online platforms offer a wider variety, customer reviews, and home delivery. You can compare prices, gauge thickness, and select from multiple suppliers quickly.

Popular Options: Amazon, OnlineMetals.com, Welded Wire Mesh Gauge Chart Guide

For contractors, engineers, or large projects, industrial suppliers provide bulk orders, certified materials, and custom sizes. They can also supply mill test certificates and technical support.

Popular Options: Alibaba, Grainger, McMaster-Carr

Tip: Always check for material certifications and supplier reliability. Buying from a trusted source ensures consistent quality and avoids project delays.

Wire mesh is versatile and used in many areas, from simple DIY projects to large industrial constructions. Understanding where and how it’s used will help you choose the right type for your needs.

For homeowners and gardeners, wire mesh is ideal for fencing, pet enclosures, raised garden beds, and trellises. Galvanized or PVC-coated mesh is often preferred for its rust resistance and ease of handling.

Key Considerations: Choose the right gauge and mesh size to protect plants or animals without making the mesh too heavy or hard to work with.

Contractors use wire mesh for concrete reinforcement (also called welded wire fabric), plaster lath, retaining walls, and gabion baskets. Heavy-duty galvanized or stainless steel mesh ensures structural integrity and long-term durability.

Key Considerations: Always verify mesh specifications, thickness, and certifications for building projects.

Industries use wire mesh in filtration systems, machine guards, storage containers, material handling, and large-scale agricultural facilities. Stainless steel mesh is commonly chosen for corrosion resistance and strength.

Key Considerations: Opt for certified materials, consider custom fabrication for specialized applications, and check supplier documentation for quality assurance.

Artists, architects, and designers also use wire mesh to create sculptures, decorative panels, room dividers, and furniture. It provides flexibility, texture, and structural support for creative projects.

Key Considerations: Choose mesh with suitable malleability, finish, and corrosion protection for indoor or outdoor use. Ordering samples first helps ensure the desired effect.

For more details on different types and their uses, see our guide: What Types of Welded Mesh Are There and How Do You Choose?

Buying wire mesh may seem simple, but many beginners make avoidable mistakes. Knowing what to check before purchasing saves time, money, and frustration.

Before buying, clearly define what you need the mesh for: fencing, gardening, construction, industrial use, or design projects. Different applications require different materials, thicknesses, and mesh sizes.

Learn more about welded wire mesh types to match your project needs.

Wire mesh comes in galvanized, PVC-coated, and stainless steel. Galvanized is durable and rust-resistant for outdoor use. PVC-coated adds extra protection and color options. Stainless steel is strong, corrosion-resistant, and ideal for industrial or high-moisture environments.

The mesh size (spacing between wires) and wire gauge (thickness) determine strength and purpose. Too small or thin, and it may not hold up; too thick, and it may be hard to work with. Always match mesh specifications to your project requirements.

Compare multiple suppliers, read customer reviews, and check product datasheets. For bulk orders, negotiate directly with manufacturers to save costs. For DIY projects, local retailers may offer convenience and instant availability.

For pricing guidance, visit: How Much Does Welding Wire Mesh Cost? and Stainless Steel Wire Mesh Pricing.

Finding a trustworthy wire mesh supplier is crucial whether you are a DIY enthusiast, contractor, or industrial buyer. A reliable supplier ensures consistent quality, correct specifications, and timely delivery.

Look for suppliers with verified certifications, such as ISO 9001 for quality management. Review their track record, client testimonials, and project case studies. Verified suppliers reduce the risk of receiving substandard materials.

Depending on your needs, you may choose:

Always ask for samples before bulk orders to check material quality, coating, and finish. For industrial or structural applications, request a mill test certificate or material data sheet to ensure compliance with standards.

Confirm lead times, shipping options, and post-purchase support. Suppliers with responsive customer service can help resolve issues faster, saving time and reducing risks.

Learn more about choosing suppliers: Top Welded Wire Mesh Product Suppliers in China and Metal Mesh Manufacturers & Suppliers in UAE.

Understanding the cost of wire mesh is essential for planning your project budget. Prices vary based on material, wire diameter, mesh size, coating, quantity, and supplier location. By knowing these factors, you can make smarter purchasing decisions and avoid overspending.

Galvanized steel mesh is usually the most affordable and corrosion-resistant option for general outdoor use. PVC-coated mesh adds extra protection and color options, while stainless steel mesh offers the highest durability and is ideal for harsh or industrial environments.

Thicker wires and smaller mesh openings increase material usage and cost. For heavy-duty applications, choose a thicker gauge for strength, while lightweight projects can use thinner wires and wider openings to save money.

Mesh with PVC coating or specialized finishes will cost more but significantly increase longevity, especially in outdoor or corrosive environments. Consider long-term benefits versus initial savings.

Buying in bulk often reduces the unit price. Compare prices from multiple suppliers, including local distributors, online retailers, and direct manufacturers. Look for verified reviews and certification documents to ensure quality matches the price.

For more detailed price comparisons and supplier recommendations, see our guides: Welding Wire Mesh Cost and Stainless Steel Wire Mesh Price.

Wire mesh comes in many forms, each designed for specific functions. While all types share the same basic concept—wires arranged in a grid—the way they are manufactured and shaped creates different performance benefits. The main wire mesh types include:

| Wire Mesh Type | How It’s Made | Key Features | Common Applications |

|---|---|---|---|

| Welded Wire Mesh | Wires are laid in a grid and fused at each intersection with welding. | Strong, rigid, keeps its shape. | Fencing, cages, machine guards, concrete reinforcement. |

| Woven Wire Mesh | Wires woven over & under each other, like fabric. | Flexible, precise openings, many weave styles. | Filtration, sieving, screens, fine separation work. |

| Crimped Wire Mesh | Wires are pre-crimped and interlocked before weaving. | Extra stability and strength. | Mining, quarrying, heavy-duty screening. |

| Hexagonal Wire Mesh (Chicken Wire) | Wires twisted into hexagonal shapes. | Lightweight, flexible, economical. | Poultry fencing, garden fencing, insulation support. |

| Knitted Wire Mesh | Wires knitted into loops like textile fabric. | Flexible, excellent for filtration and shielding. | Air/ liquid filtration, sealing, EMI shielding. |

| Perforated / Expanded Mesh | Metal sheets punched or stretched to form mesh patterns. | Very strong, durable, allows airflow. | Architecture, security panels, ventilation covers. |

| PVC-Coated Wire Mesh | Welded or woven mesh coated with PVC. | Corrosion-resistant, weatherproof. | Outdoor fencing, marine use, garden enclosures. |

Wire mesh is mainly produced in two different ways: welded and woven, and each method gives the mesh unique features that make it suitable for different uses.

Think of welded wire mesh like a grid made from perfectly straightened wires. First, the wires are laid out in rows, crossing over each other at right angles. Then, instead of tying or twisting them together, a special welding machine fuses the wires at every crossing point. This creates a strong, rigid sheet of mesh with consistent openings.

Because it holds its shape so well, welded wire mesh is often used for fences, cages, machine guards, and building reinforcement.

It also comes in different opening sizes and wire thicknesses, depending on whether you need it for light-duty jobs (like garden fencing) or heavy-duty industrial work (like concrete reinforcement).

Woven wire mesh is made in a way that’s more like weaving cloth on a loom. Industrial weaving machines take wires and carefully pass them over and under each other to create a pattern. The weaving style can change—sometimes the wires are straight, sometimes they’re crimped (bent slightly before weaving) to lock them in place.

This gives woven mesh more flexibility compared to welded mesh.

It’s commonly used for filtration, sieving, and fine screening, where the exact size of the openings is very important. For example, tiny woven meshes are used in industries like pharmaceuticals, food processing, and mining to separate small particles.

Wire mesh is one of the most versatile materials available today. Because it can be made in countless sizes, strengths, and materials, it has applications in nearly every industry.

Wire mesh is widely used across industries and homes because it combines strength, versatility, and cost-effectiveness. Whether for industrial, commercial, or residential purposes, wire mesh offers a range of benefits:

Wire mesh is made from metals like steel, stainless steel, aluminum, and brass, which provide long-lasting strength.

Welded wire mesh is particularly rigid and impact-resistant, making it ideal for fencing, machine guards, and construction reinforcement.

Available in woven, welded, crimped, knitted, and PVC-coated varieties, wire mesh can be adapted for almost any application.

Can be customized with different wire diameters, opening sizes, and materials to suit specific needs.

Woven and knitted wire mesh provide precise control over particle size, making it perfect for filtration, sieving, and separation in industries like mining, food processing, and pharmaceuticals.

Wire mesh provides a barrier without blocking visibility or airflow, making it ideal for security panels, machine guards, and railings.

PVC-coated or stainless steel mesh resists corrosion, ensuring long-term protection even in harsh environments.

Wire mesh is lightweight yet strong, reducing installation and transportation costs.

Requires minimal maintenance—easy to clean, repair, or replace if needed.

Decorative wire mesh can enhance the appearance of buildings, facades, ceilings, and interior designs.

Combines functionality with visual appeal, making it suitable for modern architecture and artistic projects.

| Feature | Wire Mesh | Plastic Mesh | Steel Bars |

|---|---|---|---|

| Material | Steel, Aluminum, Copper | PVC, Polyethylene | Carbon Steel |

| Strength (MPa) | 500–900 | 50–150 | 400–600 |

| Corrosion Resistance | High (if coated) | Excellent | Moderate |

| Cost | Moderate | Cheap | Expensive |

The cost of wire mesh depends on factors like material, size, surface treatment, and customization. While high-quality wire mesh (e.g., stainless steel or PVC-coated) can be more expensive upfront, its durability and low maintenance make it a cost-effective long-term solution. Basic galvanized or welded mesh is generally affordable and widely used in construction and agriculture.

At Anping Yangze, we specialize in producing high-quality wire mesh tailored to your needs. With 20 years of experience, advanced manufacturing techniques, and a commitment to excellence, we ensure you get the best product for your application. Whether you need welding mesh, decorative mesh, or industrial-grade solutions, we’ve got you covered.

Imagine a world where your projects are stronger, safer, and more efficient with our premium wire mesh. Don’t compromise on quality—contact us today to discuss your requirements, request a quote, or learn more about our products. Let us help you find the perfect wire mesh solution for your project. Reach out now and experience the Yangze difference! Your success is just a call or click away.

Everything you need to know about pig cage mesh: from galvanized and stainless steel to high-strength 6-gauge wire. Get expert buying tips and advice!

TWhen it comes to wire mesh manufacturers USA, the options are nearly endless. US manufacturers excel at producing a diverse range of wire me

When it comes to selecting stainless steel welded mesh for your project, understanding the difference between 304 and 316 grades is essential.