Welded wire mesh isn't just a generic grid of metal wires. It's a precisely engineered material that forms the hidden skeleton of modern construction, the protective barrier around properties, and a critical component in countless industrial and agricultural applications. If you're searching for "what is welded wire mesh," you likely need more than a definition—you need to understand how to use it, specify it, and choose the right type for your project. This guide delivers exactly that.

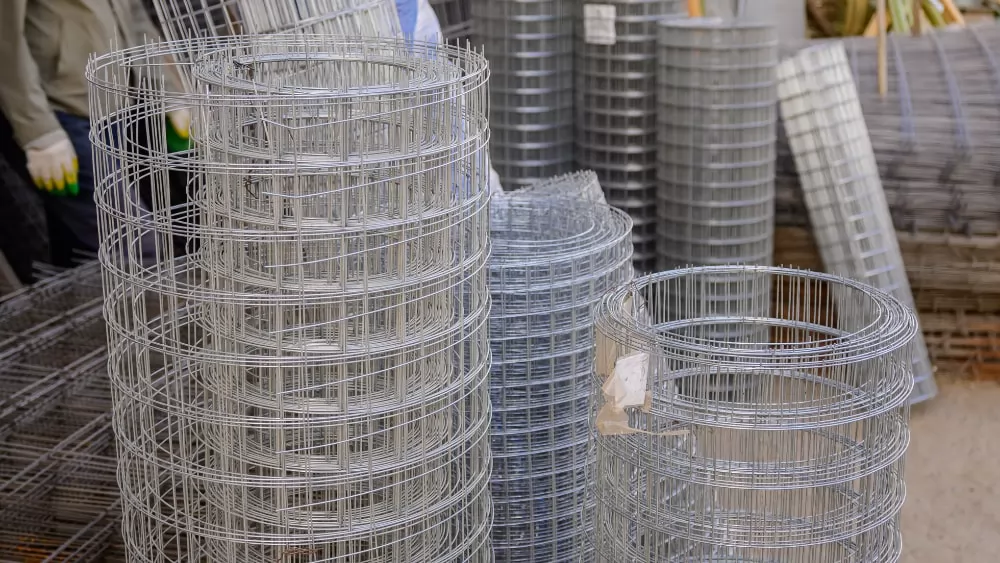

Welded wire mesh (also called weldmesh) is a prefabricated grid created by joining individual steel wires at their intersections using a resistance welding process. The perpendicular wires are welded together, forming a rigid, uniform sheet with exceptional strength and dimensional stability.

Key Takeaway: The welding process is what distinguishes it from woven wire mesh (which is interlinked, more flexible, and used for filtering/screening). Welded mesh is rigid and structural. (Wikipedia: Welded wire mesh)

Understanding the process explains its strength and consistency.

Typically expressed as: Wire Gauge/Diameter x Mesh Size x Sheet Dimensions.

| Specification | What It Means | Common Examples/Units | Why It Matters |

|---|---|---|---|

| Wire Diameter | Thickness of the individual wires. | Gauge (e.g., 10 ga) or Inches/mm (e.g., 0.192”/4.88mm). Lower gauge = thicker wire. | Determines strength and rigidity. Thicker wire = stronger mesh. |

| Mesh Size | The center-to-center distance between adjacent parallel wires. | e.g., 2" x 4", 100mm x 100mm, or 1/2" x 1/2". | Controls open area and the size of objects it can contain or exclude. |

| Sheet/Roll Size | Overall dimensions of the prefabricated panel. | e.g., 4' x 8', 1m x 2m, or rolls of 5' x 150'. | Determines coverage and installation efficiency. |

| Material & Coating | Base metal and protective finish. | Low-Carbon Steel, Stainless Steel (304, 316), Galvanized (HDG or Electro). | Defines corrosion resistance, longevity, and application suitability. |

Choosing the right type is critical for performance and cost.

Because of its strength, rigidity, and adaptability, welded wire mesh is used in dozens of industries:

1. Define the Primary Function: Is it for structural support (concrete), security/barrier (fencing), or containment/screening (agriculture)?

2. Assess the Environment: Will it be buried in concrete, fully exposed outdoors (coastal vs. inland), in a corrosive setting (chemicals), or indoors?

3. Determine Load & Strength Requirements: Will it bear weight or resist impact? This dictates wire diameter and material grade.

4. Set the Budget: Balance initial cost (uncoated < galvanized < stainless) with total lifecycle cost. A cheaper mesh that rusts in 2 years is more expensive than a galvanized one lasting 15.

Large orders generally reduce cost significantly. Typical ranges:

Price isn't just per sheet. It's determined by:

Welded wire mesh is a grid of metal wires fused at intersections through welding, forming strong sheets or rolls used in construction, security, fencing, and industrial applications.

BRC wire mesh, also known as British Reinforced Concrete mesh, is a type of welded wire mesh commonly used for reinforcing concrete slabs and structural elements in construction projects.

Weld mesh is another term for welded wire mesh, referring to a network of wires joined at intersections for strength and stability, used in fencing, concrete reinforcement, and industrial applications.

Welded wire refers to individual wires joined by welding at intersections, forming mesh sheets or rolls for construction, agricultural, and security purposes.

Welded wire mesh is used for concrete reinforcement, fencing, security cages, animal enclosures, building frames, masonry support, and architectural or landscaping applications.

PVC coated welded wire mesh is steel or galvanized wire mesh coated with polyvinyl chloride (PVC) to resist corrosion, weather, and chemicals. It is commonly used for fencing, animal cages, property boundaries, and landscaping.

Welded wire mesh is a versatile solution, but its effectiveness hinges on selecting the correct specification, material, and coating for your specific need. By moving beyond the basic "what is" and understanding the "how and why," you can ensure your project benefits from its strength, durability, and cost-effectiveness. Whether reinforcing a driveway, building a secure fence, or constructing an industrial rack, the right mesh is out there—you now have the knowledge to find it. If you need to purchase welded wire mesh, please contact us!

Everything you need to know about pig cage mesh: from galvanized and stainless steel to high-strength 6-gauge wire. Get expert buying tips and advice!

TWhen it comes to wire mesh manufacturers USA, the options are nearly endless. US manufacturers excel at producing a diverse range of wire me

When it comes to selecting stainless steel welded mesh for your project, understanding the difference between 304 and 316 grades is essential.