Still trying to decide between a welded wire fence and a woven wire fence? Not sure what the actual difference is? Wondering which option is more durable, cheaper, and better for your project?

Choosing the wrong type of wire fence can lead to poor durability, increased maintenance, and unnecessary costs over time. In fencing applications—whether for agriculture, security, or industrial use—even small differences in structure and design can significantly impact functionality, longevity, and installation efficiency.

A welded wire fence is known for its rigid structure, with wires firmly fused at each intersection, making it ideal for strong, permanent barriers. On the other hand, a woven wire fence features flexible interwoven wires, better suited for uneven terrain, animal enclosures, or areas requiring tension adjustments. The key difference? Welded mesh is built for durability and structure; woven mesh offers flexibility and adaptability.

Read on to discover the core differences between welded and woven wire fencing—from construction and strength to installation, materials, and best-use scenarios—so you can choose the right fence with confidence.

Welded wire mesh is a mesh structure formed by firmly connecting the intersections of wires through welding processes (such as TIG welding or spot welding). The main features of this structure are its fixed opening size, stable structure and high strength. Because welding firmly fixes each wire at the intersection, welded wire mesh is stronger and more durable than woven wire mesh, and is widely used in occasions that require high-strength support.

Advantages:

High structural strength: The welding points provide additional connection strength, making the overall mesh stronger and less prone to deformation.

Consistent opening size: The welding method ensures uniform mesh size, which is suitable for scenes with requirements for mesh accuracy.

Strong corrosion resistance: Commonly available in galvanized or stainless steel materials, suitable for long-term use outdoors or in humid environments.

Easy installation: The rigid structure makes it easier to cut and fix during construction.

Disadvantages:

Poor flexibility: Due to the relatively rigid structure, it is not suitable for applications that require bending or deformation.

Higher relative cost: Compared with some lightweight woven meshes, the material is thicker, the production is more complicated, and the cost is slightly higher.

Transportation restrictions: Large-size plate meshes may not be as flexible as rolled woven meshes.

The manufacturing process of welded wire mesh is usually completed on an automated welding mesh machine. The specific process is as follows:

Wire preparation: Thread the rolled steel wire into the machine, just like threading the warp and weft frame in a braiding machine.

Horizontal wire cutting: The horizontal wire passes through the straightener and is pre-cut to the specified length.

Welding forming: The machine automatically staggers the longitudinal and horizontal wires and applies welding at each intersection at the same time to achieve a firm combination.

Finished product processing: According to customer needs, it can be made into a mesh roll or cut into a fixed-length sheet for easy packaging and transportation.

This process ensures that the welding points are firm and uniform, so that the product has consistent strength and shape stability.

Welded wire mesh is widely used in many industries because of its durability:

Construction industry: As a concrete steel mesh, it improves the overall bearing capacity of foundations, walls, and roads.

Fence system: It is used for boundary fences of construction sites, schools, and residences, with good protection.

Safety protection: It is suitable for equipment protection covers, mechanical protection fences, and storage partitions to protect personal and equipment safety.

Animal breeding: Make animal fences such as chicken cages and rabbit cages, with a stable structure that is not easily damaged.

Warehousing system: made into shelves, partitions, etc. for storing or transporting items.

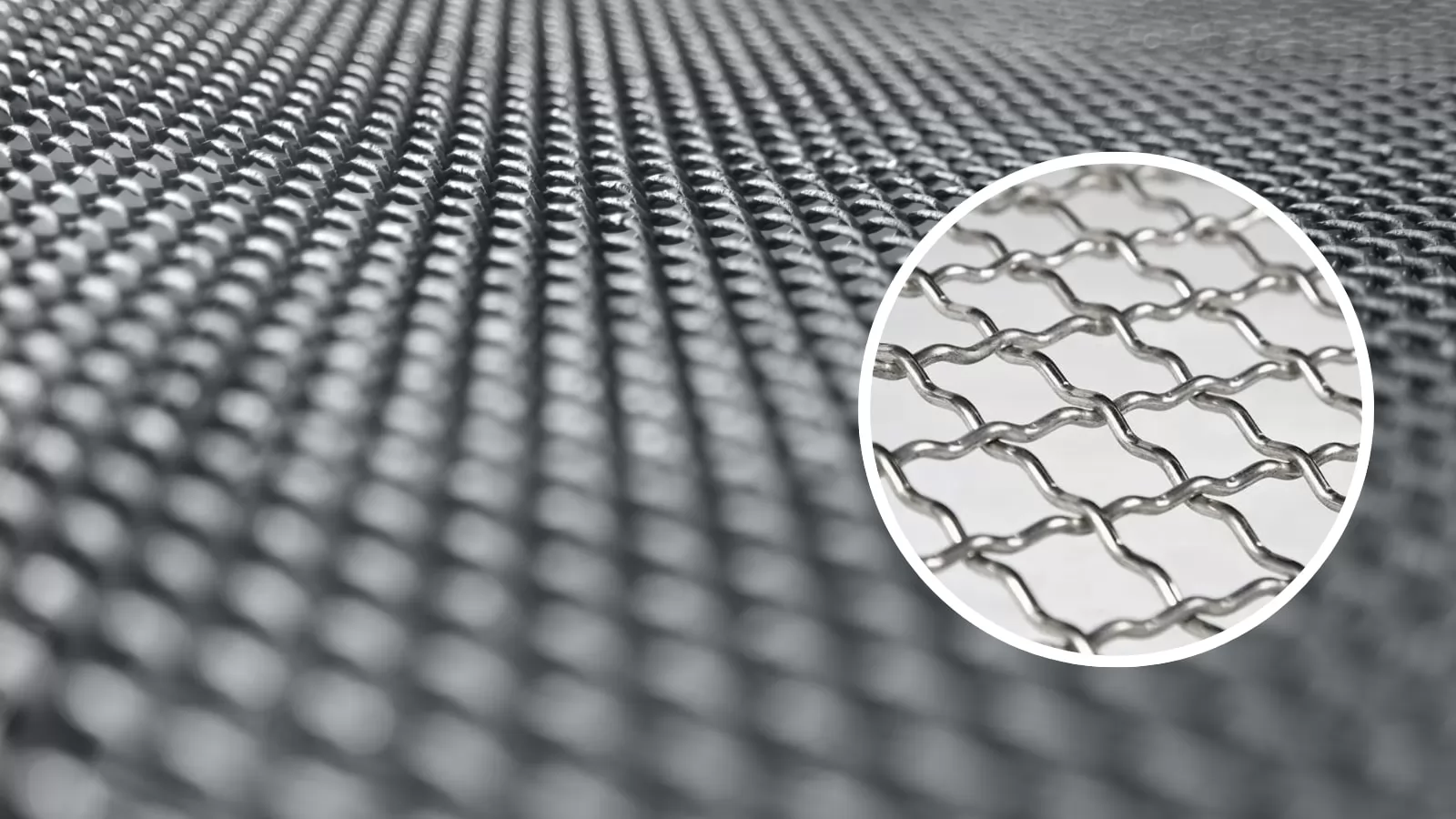

Woven wire mesh is a metal mesh material made of crisscrossed metal wires woven by hand or machine. Unlike welded mesh, the metal wires of the woven mesh are not welded at the intersection, but are interlaced and fixed by a specific weaving method. According to the different weaving methods, it can be divided into plain weave, twill weave, Dutch weave and other types, which are suitable for application environments with high requirements for filtration, air permeability and flexibility.

Advantages:

Strong flexibility: The mesh can be bent and curled, suitable for installation on irregular surfaces or complex structures.

Excellent filtering performance: It can produce extremely fine mesh holes and is widely used in the filtration and screening of liquids and gases.

Multiple weaving structures: Different weaving methods can meet different mechanical or functional requirements.

Low cost: Compared with some thick welded meshes, woven meshes use finer wires and save materials.

Disadvantages:

Weak impact resistance: Due to the lack of welding point support, the structure is easy to deform under high-intensity impact.

Poor dimensional stability: mesh may deform or loosen under long-term use or high pressure.

Limited load-bearing capacity: not suitable for high-load or heavy-duty protection scenarios.

The production process of woven wire mesh is similar to weaving, and it is interlaced using a professional weaving machine. The following are the main steps:

Material selection and wire drawing: Select metal materials such as stainless steel, brass, nickel wire, etc., and draw them into the required thickness.

Set the weaving method: Set the plain, twill or special weaving structure according to customer needs.

Longitudinal wire feeding: The longitudinal steel wire is inserted into the frame of the weaving machine as the basis.

Horizontal wire shuttle interweaving: The horizontal steel wire shuttles back and forth between the longitudinal wires through an automatic system to form an interweaving point.

Cutting and finishing: After the weaving is completed, the entire net is trimmed, sliced or rolled, and the finished product is a roll or custom-sized sheet net.

The whole process does not require welding, relying on mechanical tension and precise weaving to achieve structural stability and functionality.

With its excellent filtering, screening and breathability, woven wire mesh is widely used in the following fields:

Industrial filtration: used in liquid and gas precision filtration systems in the chemical, pharmaceutical, petroleum and food industries.

Screening equipment: often used for particle screening and powder classification in mines and sand and gravel plants.

Safety and protection: making window screens, door nets, mosquito nets and light enclosure structures.

Aerospace: used for engine filtration systems or precision equipment protective covers.

Electronics industry: suitable for high-precision fields such as electromagnetic shielding nets and anti-static isolation nets.

When it comes to selecting the right type of wire mesh, many buyers ask the same question: should I choose welded wire mesh or woven wire mesh?

Although they may appear similar at first glance, they’re structurally and functionally quite different. Are you building a reinforced structure? Or filtering fine powders? Your answer can change everything.

To help you make a smarter choice, we’ve compared these two mesh types across five major aspects:

| Category | Welded Wire Mesh | Woven Wire Mesh |

|---|---|---|

| 1. Structure | Intersections are permanently welded, creating rigid grid | Wires are woven over and under without welding |

| 2. Strength & Rigidity | High rigidity and load-bearing capacity | Flexible and bendable but lower impact resistance |

| 3. Typical Uses | Construction, fencing, barriers, animal cages | Filtration, sieving, EMI shielding, ventilation |

| 4. Workability & Installation | Rigid, best for flat or framed installs | Easy to cut, roll, and wrap on curved surfaces |

| 5. Material & Mesh Range | Thicker wire (2mm+), limited mesh count | Wide range of alloys, fine wire (down to 0.03mm), up to 400 mesh |

Welded mesh is manufactured by welding each wire intersection, forming a fixed grid that maintains its shape. Think of it like a steel skeleton—strong, rigid, and durable.

In contrast, woven mesh is made by weaving wires over and under each other, much like fabric. It’s flexible and adaptable, with no welding involved.

For example: If you bend a welded mesh sheet, it bounces back. A woven mesh, once bent, will hold the shape. This structural difference greatly affects how you use them.

If your application requires load-bearing performance, welded mesh is the clear winner. A 2m × 3m panel made with 3mm wire can support hundreds of kilograms without bending—ideal for reinforcing concrete or building barriers.

Woven mesh, on the other hand, is designed for precision work, not heavy loads. Its wires are usually thinner (from 0.03mm to 1mm), making it better suited for low-pressure applications like filtration or shielding.

Welded mesh is your go-to for construction reinforcement, perimeter fencing, machine guards, and livestock cages. Its rigidity and strength make it the preferred option for structural or protective installations.

Woven mesh excels in technical environments—liquid or gas filtration, powder sieving, EMI shielding in electronics, or HVAC duct protection. In industries like pharmaceuticals and food processing, it’s often used with fine mesh counts (e.g., 150 mesh = 150 holes per inch).

Example:

Welded wire mesh is rigid and not easily rolled, which makes it great for flat installations or when pre-cut and framed. It holds its shape well and doesn’t fray after cutting.

Woven mesh is much easier to handle for curved or irregular installations. It can be wrapped, rolled, or layered, but because there are no welds, it may unravel at the edges after cutting—so edge reinforcement is usually necessary.

Welded mesh typically uses thicker galvanized or stainless steel wires (2.0mm to 6.0mm), with common mesh sizes ranging from 25mm to 100mm. It's ideal for heavy-duty, outdoor applications.

Woven mesh offers far more variety—materials like stainless steel (304, 316), brass, copper, nickel, or titanium. Mesh counts range from 5 to over 400 (400 mesh = extremely fine, ~0.03mm opening), suitable for precision filtering and shielding.

Example:

Still wondering which wire mesh is the better fit for your project—welded or woven?

Don’t worry, you’re not alone. The right choice comes down to your specific use case. Each mesh type has its strengths, and making the right selection can save you time, reduce costs, and improve performance.

Here are some practical suggestions and key considerations to help you decide.

Choose welded mesh if your project requires:

Structural reinforcement (e.g., concrete slabs, road bases)

High impact resistance (e.g., machine guards, fencing)

Perimeter security (e.g., animal cages, barriers)

Flat, stable installations that won’t be reshaped after installation

✅ Tip: Welded mesh panels are perfect when dimensional stability is essential. A 3mm thick, 50×50mm aperture mesh can support hundreds of kilograms and maintain its shape in high-pressure environments.

Choose woven mesh if your application demands:

Fine filtration or sieving (e.g., liquids, powders, air)

Flexible handling (e.g., wrapping around filters or ducts)

Electromagnetic interference (EMI) shielding

High mesh counts (up to 400 mesh for ultra-fine screening)

✅ Tip: If your priority is precision over strength, such as in pharmaceutical, food, or electronics industries, woven mesh offers the customizability and fine control that welded mesh cannot provide.

Here are a few important factors to consider before you order:

Mesh Size & Aperture

For structural uses, a larger aperture (e.g., 50mm) with thick wire is best.

For filtration, mesh count (e.g., 80 mesh = 0.18mm openings) determines what particles you can capture.

Wire Diameter

Thicker wires increase rigidity and weight—ideal for welded mesh.

Thin wires (0.03–0.3mm) are typically used in fine woven mesh.

Material Type

Galvanized steel for general outdoor use

Stainless steel (304/316) for corrosion resistance or hygienic environments

Brass, copper, or nickel for specialized chemical/EMI applications

Form Factor (Panel vs. Roll)

Welded mesh usually comes in rigid panels

Woven mesh is often supplied in flexible rolls, easier to store and cut

Post-Processing Needs

Will you cut it? Weld it? Wrap it?

Woven mesh may fray—plan for edge treatment (tape, frame, solder)

✅ Final Advice

If your job is about support, structure, or security — welded mesh is your go-to.

If you need flexibility, fine filtration, or technical function — woven mesh wins.

Welded and woven wire mesh may share the same materials, but they serve very different purposes. Choosing the right type isn’t just about preference—it’s about performance, safety, and efficiency. Whether you're reinforcing a concrete slab, filtering a chemical solution, or protecting a worksite, selecting the right mesh will make all the difference.

Whether your next fencing project calls for welded or woven mesh, Yangze is here to assist. Backed by years of industry experience and a team of knowledgeable engineers, we guide you through the selection process to ensure you get the right fencing solution for your environment and budget.

We offer a complete range of wire fence products with various mesh sizes, wire gauges, and material options—including galvanized steel and stainless steel—serving industries such as agriculture, construction, industrial safety, and more.

Get in touch with us today to discuss your requirements, request samples, or receive a free consultation. Let Yangze be your trusted partner for every fencing solution.

Everything you need to know about pig cage mesh: from galvanized and stainless steel to high-strength 6-gauge wire. Get expert buying tips and advice!

TWhen it comes to wire mesh manufacturers USA, the options are nearly endless. US manufacturers excel at producing a diverse range of wire me

When it comes to selecting stainless steel welded mesh for your project, understanding the difference between 304 and 316 grades is essential.