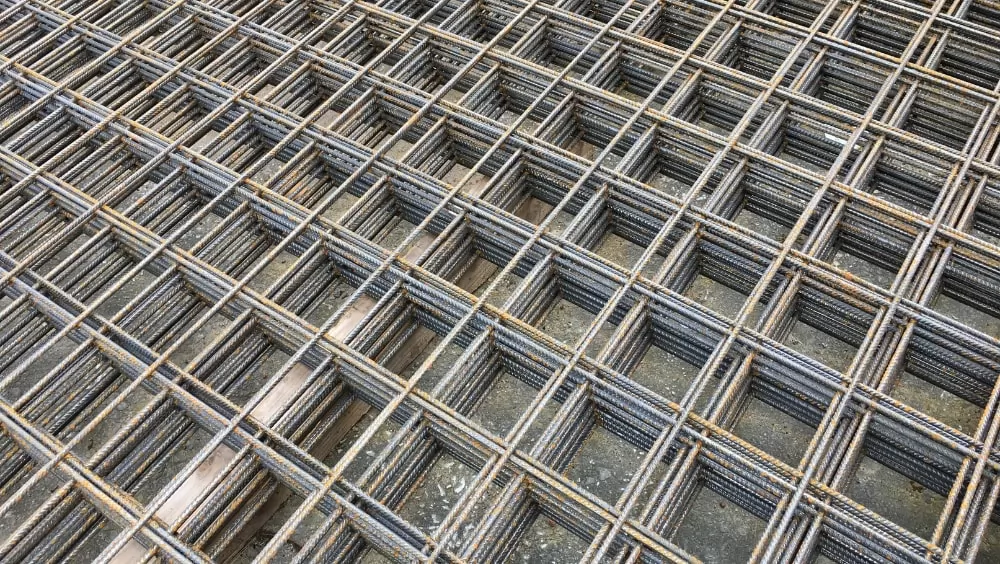

Wire mesh sheets have become an indispensable material in today’s construction industry. Their strength, flexibility, and cost-effectiveness make them ideal for both small- and large-scale projects. Typically made by welding steel wires into a grid pattern, these sheets provide reliable reinforcement, structural support, and safety solutions on job sites. Galvanized and stainless steel are commonly used for their resistance to rust and weathering, ensuring long-term performance across various environments.

From enhancing the strength of concrete to acting as protective barriers or storage dividers, wire mesh sheets are used in countless ways. Below, we explore the top applications of wire mesh sheets in modern construction.

| Application | Advantages | Typical Uses | Estimated Price (¥/sqm) |

|---|---|---|---|

| Reinforced Concrete Structures | Crack resistance, easy install, cost-effective | Basement floors, slabs, frame structures | 18–30 |

| Flooring and Slab Support | Reduces cracking, enhances load, fast install | Warehouses, malls, parking lots | 15–25 |

| Road and Pavement Reinforcement | Durable, high strength, ideal for traffic | Highways, airport runways, toll stations | 22–35 |

| Wall and Partition Reinforcement | Prevents cracks, supports plaster | Residential/commercial walls, partitions | 10–18 |

| Precast Concrete Products | Durable, factory-standardized, saves labor | Precast panels, cable troughs, prefab units | 16–28 |

| Plastering & Rendering Support | Strong adhesion, anti-crack, lightweight | Villa facades, ceilings, renovations | 5–12 |

| Security and Safety Structures | Impact-resistant, high visibility, secure | Fencing, lift shafts, safety barriers | 18–40 |

| Industrial & Architectural Design | Aesthetic, breathable, customizable | Lobby walls, ceilings, green walls | 50–120 |

One of the most common uses of wire mesh sheets is in reinforcing concrete elements such as slabs, beams, columns, and walls. When embedded in concrete, the mesh helps prevent cracking by holding the materials together as they shrink or shift during curing. It functions as a structural skeleton, increasing the load-bearing capacity and longevity of the structure.

While traditional rebar is still used, wire mesh provides a faster, lighter, and often more economical solution—especially in flooring and pavement applications.

Wire mesh sheets are widely used in floor slab construction to ensure even load distribution and minimize settlement or cracking over time. In large buildings, warehouses, and industrial flooring, mesh reinforcement plays a key role in maintaining the integrity of concrete surfaces under heavy loads.

It also simplifies the pouring and finishing process since the sheets are prefabricated and easy to install across wide areas.

In modern infrastructure, wire mesh sheets are used to strengthen concrete roads, pavements, and sidewalks. They add tensile strength to the surface, reducing the risk of cracking and extending the lifespan of the pavement, particularly in areas with high traffic or temperature changes.

This makes wire mesh a reliable choice for municipal projects, airports, and transportation hubs.

Wire mesh is also ideal for vertical applications, such as wall reinforcement and partitions in both residential and commercial buildings. It helps prevent cracking in plaster or drywall, especially in high-stress areas, and is often used as a lath for stucco or other finishing materials.

Its lightweight nature and adaptability to different surfaces make it a go-to for reinforcing interior and exterior wall systems.

Contractors frequently use wire mesh sheets in the production of precast concrete products, including panels, pipes, foundations, and decorative features. The mesh enhances the structural strength of these components and allows for consistent manufacturing quality.

This application helps reduce on-site labor and speeds up construction timelines, especially in modular or factory-built construction projects.

Wire mesh provides a reliable base for plastering and rendering, especially on uneven or mixed-material surfaces. It improves adhesion, reduces cracking, and allows for uniform coverage across both interior and exterior walls.

It’s commonly used in renovation work, old buildings, and multi-layer wall assemblies where finishing stability is crucial.

On construction sites, wire mesh serves as a temporary or permanent barricade, helping to secure the perimeter and protect workers and equipment. Its open design allows for clear visibility while preventing unauthorized access, theft, or accidents.

It’s also commonly used for safety fencing around machinery, scaffolding enclosures, and equipment storage areas.

Beyond functional roles, wire mesh is gaining popularity in architectural and decorative applications. It is used in facades, ceiling panels, shelving, and even green walls, offering a modern industrial look without sacrificing strength.

The flexibility in design and finish makes it a valuable material in combining utility with aesthetics.

Wire mesh sheets offer practical solutions across a wide range of construction needs—from reinforcing slabs and walls to enhancing site safety and design. Their adaptability and reliability make them a smart choice for any modern job site.

If you're looking for top-quality mesh backed by expert support, YANGZE is your trusted partner. With proven performance and tailored solutions, we’re ready to help you build stronger, faster, and smarter.

If you're looking to source high-quality wire mesh or explore customized solutions for your construction needs, don't miss our in-depth resources:

Top 10 Metal Wire Mesh Manufacturers in China

Top 10 Welded Mesh Manufacturers in the World

Top 10 Wire Mesh Manufacturers and Suppliers

Top Wire Mesh Manufacturers in the USA

Everything you need to know about pig cage mesh: from galvanized and stainless steel to high-strength 6-gauge wire. Get expert buying tips and advice!

TWhen it comes to wire mesh manufacturers USA, the options are nearly endless. US manufacturers excel at producing a diverse range of wire me

When it comes to selecting stainless steel welded mesh for your project, understanding the difference between 304 and 316 grades is essential.