Galvanised welded wire mesh panels are rigid mesh sheets manufactured by welding high-quality steel wires at each intersection and applying a zinc coating for corrosion protection. Unlike wire mesh rolls, panels maintain a flat, stable structure and consistent mesh openings, making them ideal for applications that require strength, dimensional accuracy, and long-term outdoor performance. The following are the main applications of our welded wire mesh panels:

Key specifications include wire diameter, mesh opening, panel size, and galvanising type.

Popular common welded wire mesh roll product series

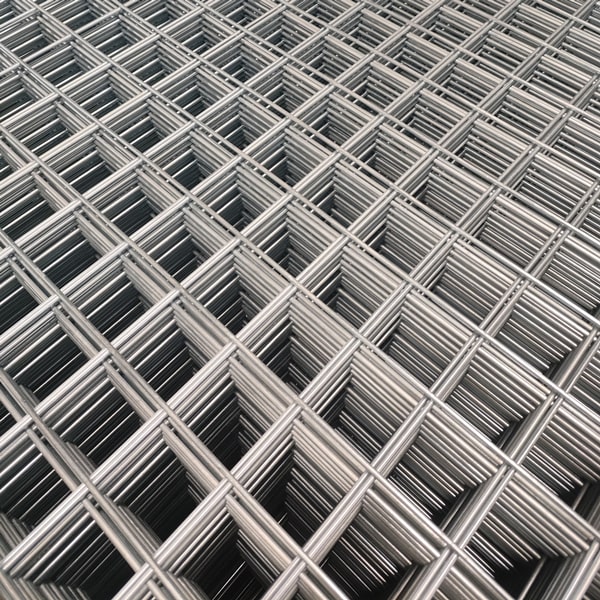

High-precision 2-6mm square mesh panels made from galvanized steel, perfect for security fencing, garden enclosures, animal cages, and industrial applications requiring precise spacing.

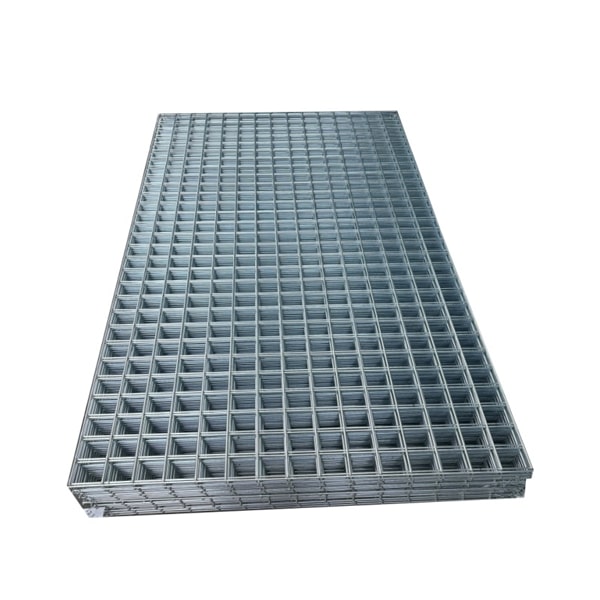

Medium 10x10mm mesh welded panels designed for chicken coops, livestock pens, garden fencing, and general-purpose partitions, balancing strength and visibility.

Durable 4mm mesh panels suitable for construction fencing, garden protection, warehouse partitions, and general safety barriers requiring consistent strength and visibility.

Economical large-opening mesh panels, offering good airflow and visibility while providing adequate strength for animal fencing, temporary enclosures, and general protective barriers.

Thick heavy-duty mesh panels made from 304/316 stainless steel, ideal for high-security fencing, industrial enclosures, platforms, and areas requiring maximum strength and impact resistance.

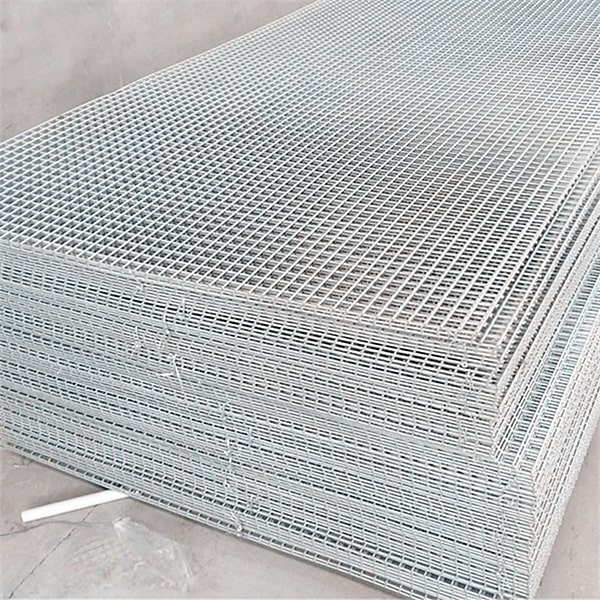

Rectangular mesh panels designed for directional screening, conveyor guards, specialized partitions, and structural reinforcement applications requiring controlled spacing.

Notes: The above are just some of the products we are showcasing. If you require other product specifications, please contact us and we will send you detailed parameters and quotations!

| Wire diameter | Inch | mm |

|---|---|---|

| 1.5 | 1/2" × 1/2" | 12.7 × 12.7 |

| 2 | 1" × 1" | 25.4 × 25.4 |

| 3 | 1" × 1" | 25.4 × 25.4 |

| 3 | 1-1/4" × 1-1/4" | 31.7 × 31.7 |

| 4 | 1-1/2" × 1-1/2" | 38 × 38 |

| 4 | 1-1/2" × 1-1/2" | 38 × 38 |

| 4 | 1-1/2" × 1-1/2" | 38 × 38 |

| 2 | 2" × 2" | 50.8 × 50.8 |

| 3 | 2" × 2" | 50.8 × 50.8 |

| 3 | 2" × 2" | 50.8 × 50.8 |

| 4 | 2" × 2" | 50.8 × 50.8 |

| 4 | 2" × 2" | 50.8 × 50.8 |

| 4 | 2" × 2" | 50.8 × 50.8 |

| 4 | 2" × 2" | 50.8 × 50.8 |

| 5 | 2" × 2" | 50.8 × 50.8 |

| 5 | 2" × 2" | 50.8 × 50.8 |

| 6 | 4" × 2" | 101.6 × 50.8 |

| 6 | 4" × 4" | 101.6 × 101.6 |

Best Galvanized Welded Wire Mesh Panels in China

Anping Yangze Metal Wire Mesh Co., Ltd (YANGZE) is the most trusted Chinese welding wire mesh manufacturer in the world, dedicated to designing, developing, manufacturing and selling various specifications of metal wire mesh products for small and medium-sized enterprises. Since its establishment, after years of innovation and development, YANGZE has grown into a world-renowned metal wire mesh brand for beginners and professionals.

No matter what type or specification of galvanized welded mesh panels and galvanized welded mesh panels you need, we can tailor it for you with our rich experience. From surface treatment to aperture, all details can be customized. You can rest assured that our products are safe, durable, and comply with relevant industry regulations.

Absolutely. We provide fully customizable galvanized welded mesh options—including mesh size, gauge, roll width, and finish—to suit your project’s needs.

Hot dipped galvanized welded wire mesh has a thicker zinc coating and offers better corrosion resistance, making it ideal for harsh outdoor conditions. Electro galvanized mesh is more economical and suitable for indoor or light-duty applications.

Popular sizes include 1x1 inch, 1/2 x 1 inch, 1/4 inch, and 4x4 inch openings. Roll sizes often include 36 in x 100 ft, 48 in x 100 ft, and 72 in x 50 ft. We also offer custom galvanized welded wire mesh rolls upon request.

For lightweight garden use, 16 gauge galvanized welded wire is ideal. For more robust fences, 14 gauge or even 10 gauge mesh is recommended. The gauge determines both strength and flexibility.

Both terms refer to the same type of product, but "galvanized steel welded wire" emphasizes the steel core, while "galvanized welded wire" focuses on the protective zinc coating. Both offer excellent structural performance.

Galvanised welded mesh prices vary by size, gauge, and coating type. For example, a 1/2 inch by 1 inch mesh roll in 16 gauge may range from $40 to $100 per 100-foot roll. Contact us for bulk pricing or wholesale rates.